Full contact HC IFR

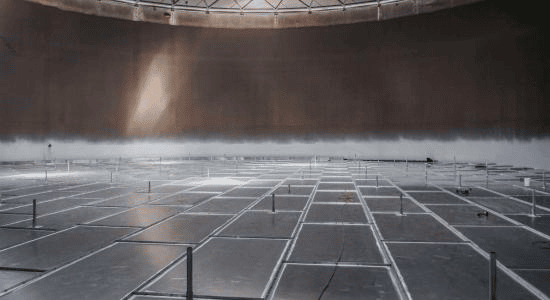

The CTS direct contact HC (Honeycomb reinforced) IFR consists of aluminium panels with an internal light and strong Honeycomb structure (HC). Every panel is fully seal welded at the factory, using an automated welding machine. After welding all modules are pressure tested at a suitable test pressure. This to ensure tightness. At the project site the panels are connected using the patented connection system. As the direct contact roof covers the surface of the stored product almost completely the emission reduction will typically exceed 98%. The roof is also very low in height, maximizing storage tank capacity. All roof penetrations and the seal rim are equipped with an 150 mm. high upstanding rim to avoid any product on the roof. Reviewing the buoyancy of the HC IFR for a specific gravity of the stored product of 0.7 will usually result in 350% excess buoyancy according API 650 Appendix H. Only stainless steel and aluminium hardware is used in the roof. HC IFR’s are available with a multitude of seals and seal combinations, as follows:

- CTS60 single and CTS70 double wiper seals

- CTS90 stainless steel shoe plate seal, liquid mounted

- CTS80 compression type shoe plate seal, liquid mounted

As the roofs float in full contact with the product eliminating vapor space under the roof and are tested as fire-safe they do allow configuring fire-fighting infrastructure on the basis of a rim-fire, per NFPA 11.

Advantages full contact HC IFR;

- Very strong IFR structure

- Suitable for full scale Nitrogen pigging and Nitrogen stripping

- Compatible with Butterworth cleaning routines

- Tested as fire-safe

- Can be equipped with a foam dam

- Fire-scenario is a rim-fire (NFPA 11)

- All modules are factory seal welded, tested and certified

- IFR cannot sink.